Ministry of the Environment, Japan

-

WP:World premiere

Product exhibited for the first time in the world at the Tokyo Motor Show

-

JP:Japan premiere

Product that has arleady premiered abroad, but being exhibited for the first time in Japan at the Tokyo Motor Show

NCV(Nano Cellulose Vehicle) Concept Car

NCV(Nano Cellulose Vehicle) Concept Car

Reference exhibits

- Cellulose nanofiber(CNF)is a material composed of nanosized cellulose fibrils. This plant-derived material, which offers high strength and high modulus is expected as the next generation material. The Ministry of Environment of Japan proposes a future car contributing to reduction in the emission of carbon dioxide from automobiles. The NCV (Nano Cellulose Vehicle) concept car installs as much CNF automotive parts as possible and the weight of the car has also been reduced by more than 10% from the standard weight. Since CNF is a carbon-neutral material, it can be expected not only to reduce CO2 emissions during driving due to weight reduction, but also to reduce CO2 emissions through the life cycle of automotive product.

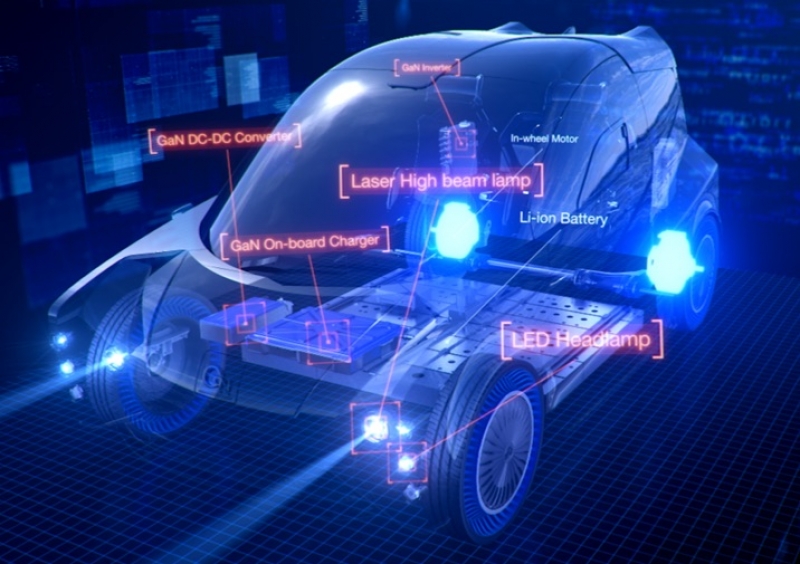

All GaN Vehicle

All GaN Vehicle

Reference exhibits

- All GaN Vehicle (AGV) is a compact sports electric mobility designed for an urban usage targeted a wide range of age groups from a younger generation to a middle-aged generation. AGV is a next generation eco-friendly mobility powered by GaN electronics such as a driving inverter, a DC-DC converter, etc. GaN LEDs and laser lighting devices are also installed. In-wheel motor is adopted in a drive system to secure a degree of freedom for a design of an interior space, and a cabin space of 2+α is designed on the short body with 3m. Maintenace-free airless tires are adopted for sharing serices, etc. Furthermore, CFRP material is adopted for suspensions and airless tires to secure light weight and high rigidity.

Battery Carrier(PP-CNF composite)

Reference exhibits

- 1. Achieved 30% weight reduction by using the biocomposite (PP-CNF) to replace metal component.

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Intake Manifold(PA6-CNF composite)

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

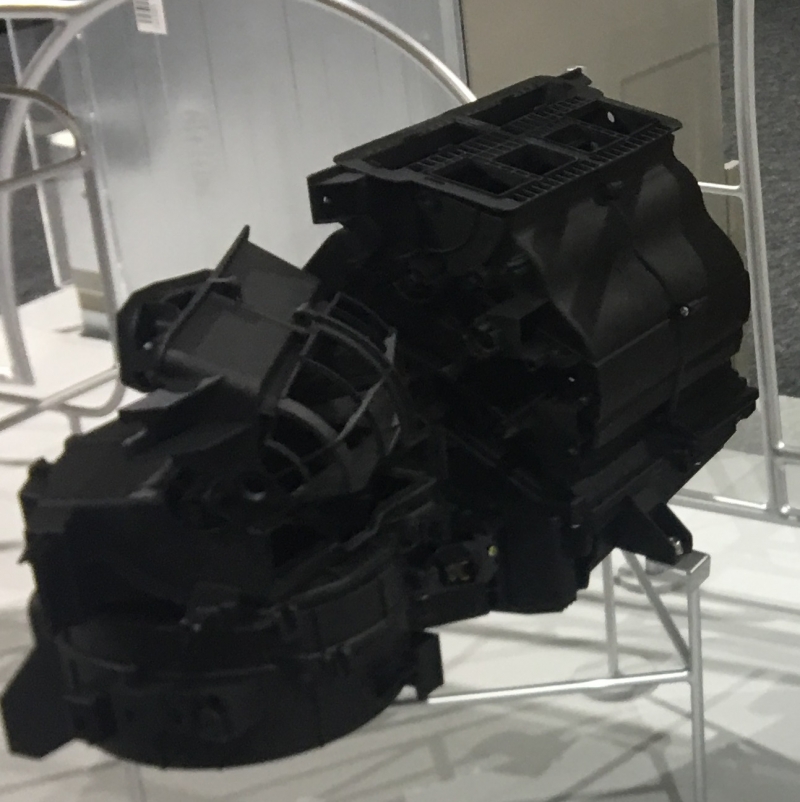

Air Conditioner Case(PO-CNF composite)

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

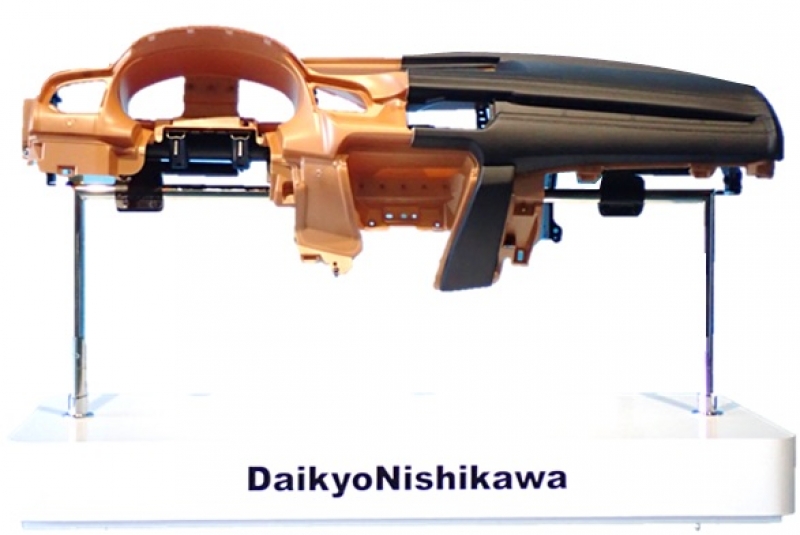

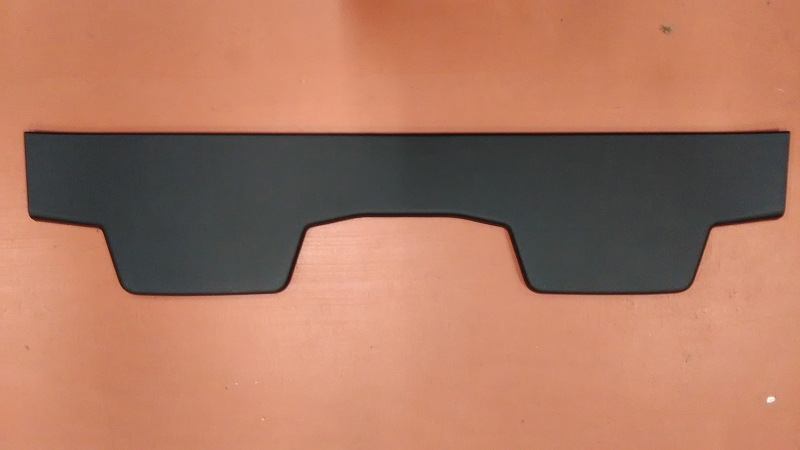

Instrument Panel(PP-CNF composite)

Reference exhibits

- 1. Achieved more than 20% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Hatchback(PA-CNF composite)

Reference exhibits

- 1. Achieved more than 20% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Door Trim(PP-CNF composite)

Reference exhibits

- 1. Achieved 15% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Roof Panel(PC-CNF)

Reference exhibits

- 1. Achieved 20% weight reduction (compared to resin glass) by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

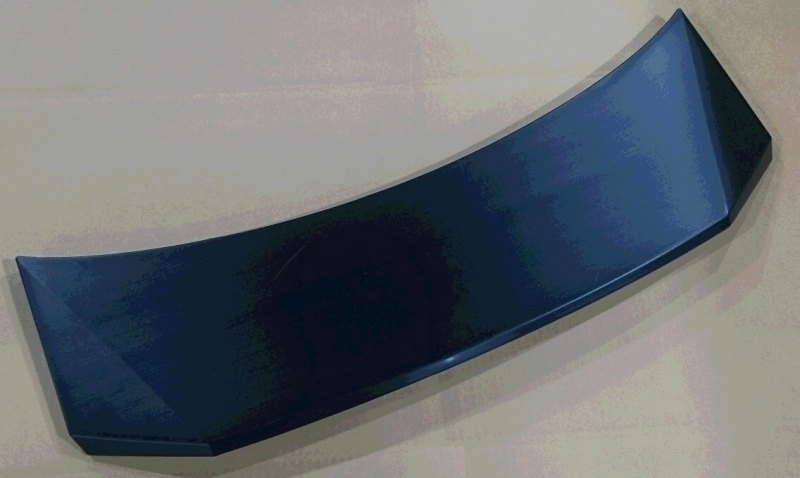

Rear Spoiler(PP-CNF composite)

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Undercover(PP-CNF composite)

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

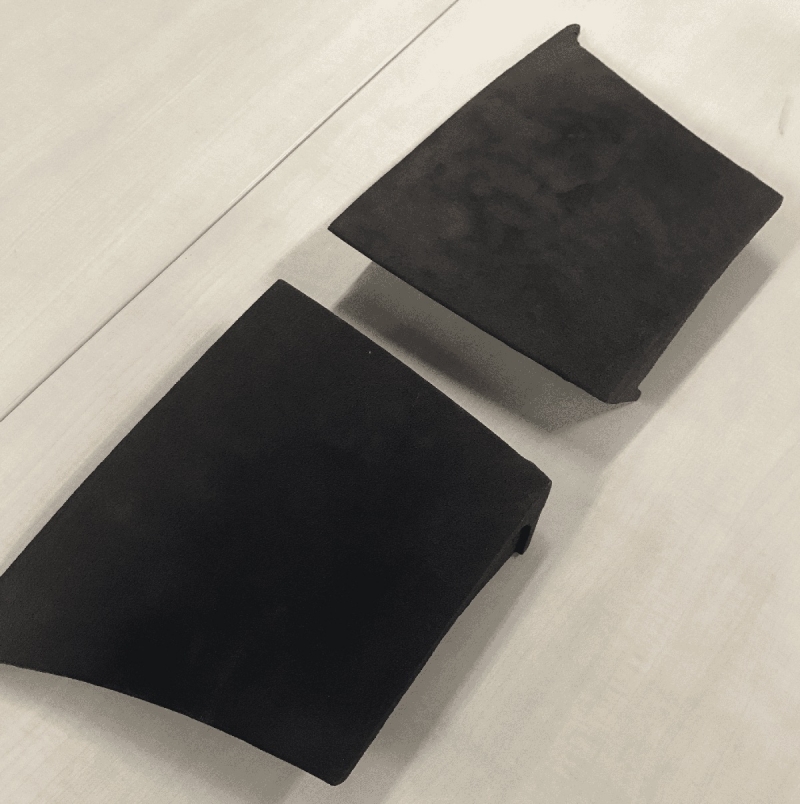

Interior Trim(PP-CNF composite)

Reference exhibits

- 1. Achieved more than 20% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Plating Parts(PA6-CNF composite)

Reference exhibits

- 1. Achieved more than 20% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

3D Prineted(Powder Bed Fusion) Parts

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Roof Side Rail(Aluminum Tube wound with CNF-paper)

Reference exhibits

- 1. More than 30% weight reduction is expected by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Large-sized Structural Parts (Resin Transfer Molding) (Epoxy-CNF)

Reference exhibits

- 1. Achieved more than 50% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Automobile Hood(CNF100% Molding)

Reference exhibits

- 1. Achieved more than 50% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Automotive Sheet(PE-CNF composite)

Reference exhibits

- 1. Achieved more than 10% weight reduction by using the CNF(Cellulose Nanofiber).

2. Utilizing CNF, a carbon neutral material, contributes not only to the reduction of CO2 emissions during driving due to weight reduction, but also to the reduction of CO2 emissions through the life cycle of the product.

Eco drive simulator

Others

- Using a driving simulator, you can experience ecodriving and learn about eco-friendly driving skills including “soft acceleration” that aim to reduce environmental load, consume less fuel, and lead to a reduction in CO2 emissions.

Eco drive e-learning content

Others